Bag Filter Design Calculation Xls

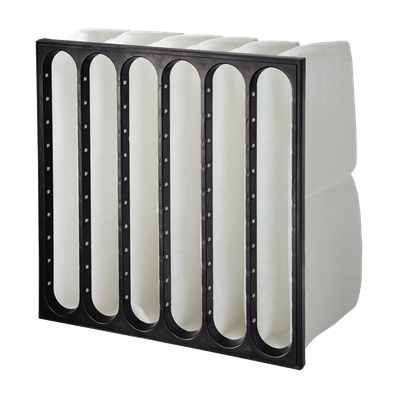

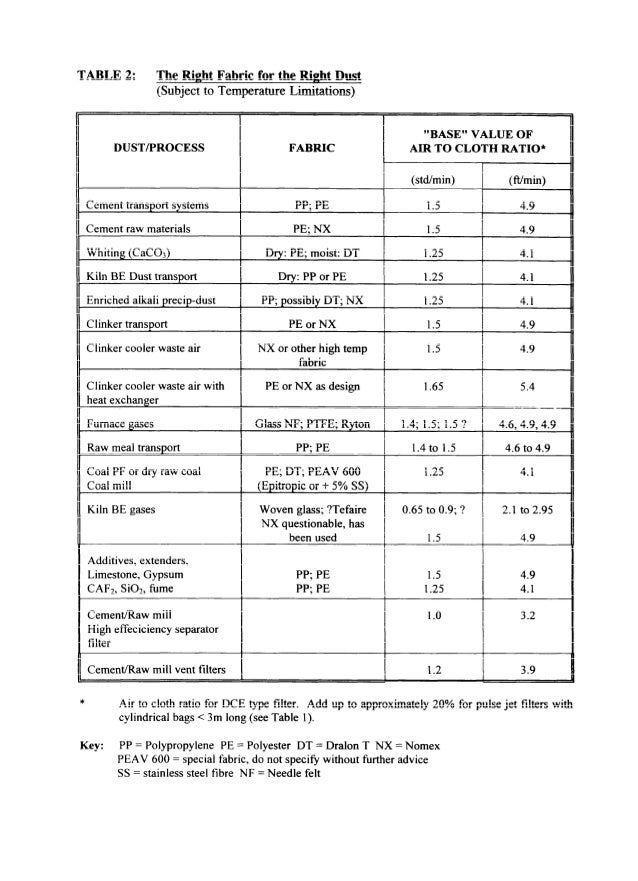

Bag filter design calculation xls. Fabric filters collect particles with sizes ranging from submicron to several hundred. 8425 2780 1811 396. Bag filter design calculation xls.

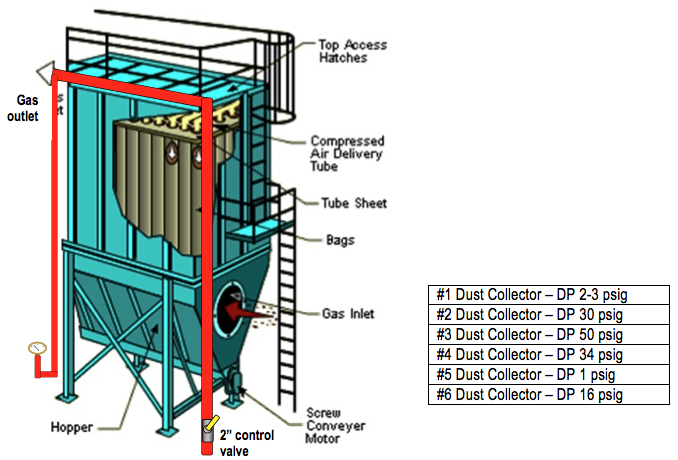

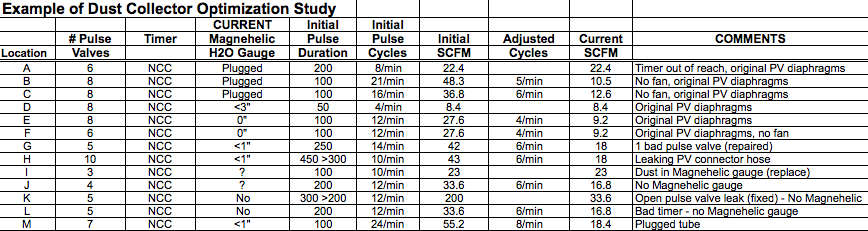

The filter is operated cyclically alternating between relatively long periods of filtering and short periods of cleaning. To determine the appropriate filter size we must study the air-. The Bag house s in the Bag house.

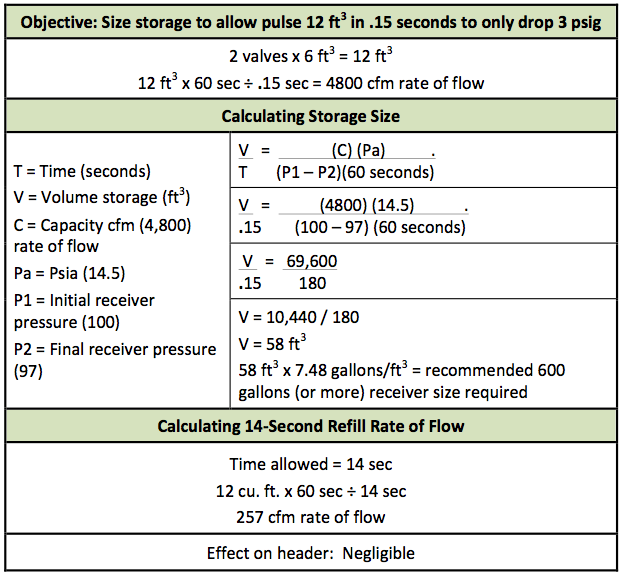

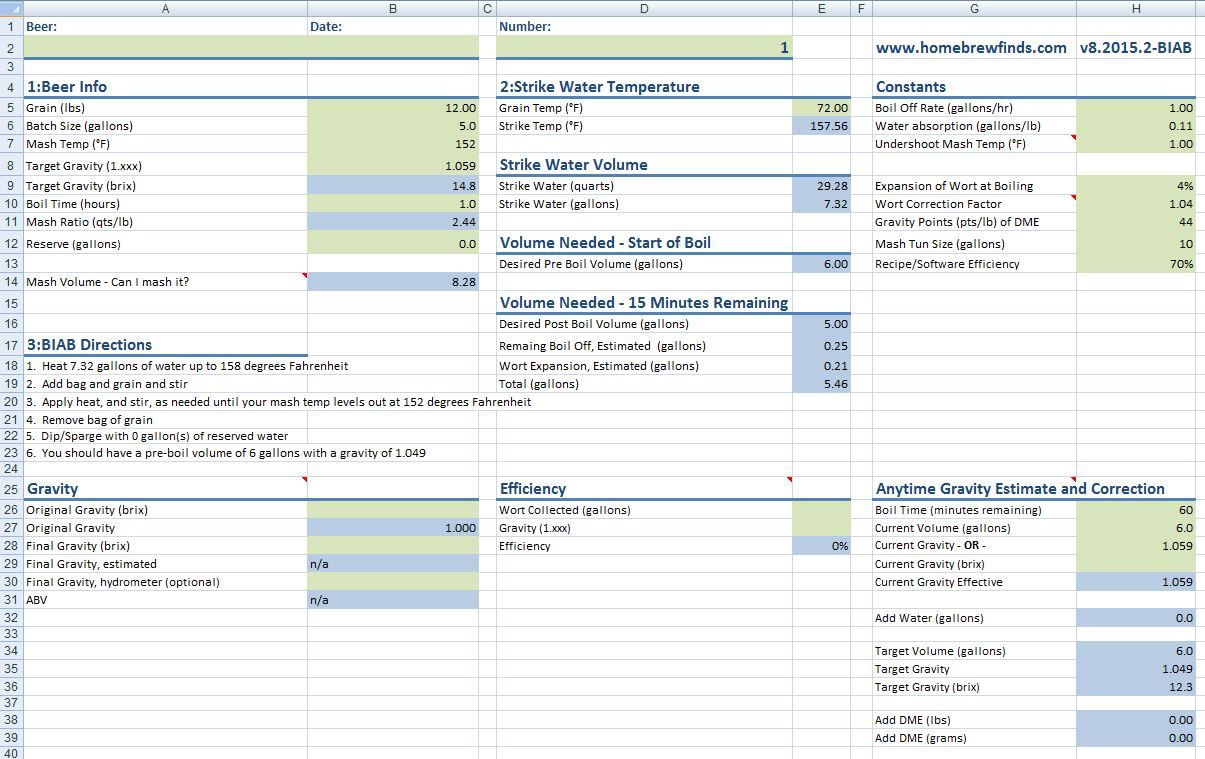

Step 1Select the type of bag micron rating and flow rate determine the pressure drop for water 1 cps 68F for a size 2 bag. SYSTEM PRESSURE DROP PS PH PB When sizing new applications the PS should be 20 PSI or less. There is no single value for bag reach but typical units have a value of 3 or 4.

Bag filter design calculation xls. Bility is called bag reach and is the maximum number of rows from the nearest walkway. Pressure drop caused by the housing PH with the bag basket in place plus the pressure drop caused by the filter bag PB.

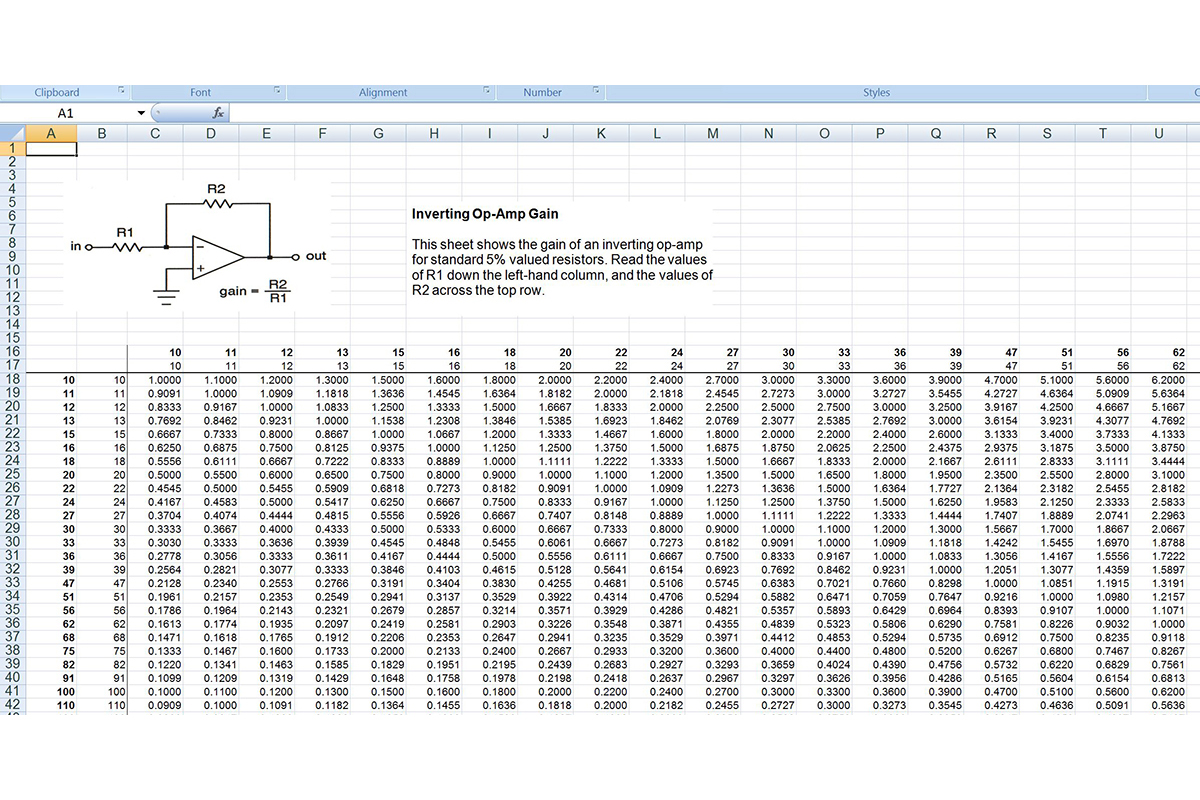

Filter Bag Filter Bags Superior Sterilizer Processing Mushroom Filter Bag From China. Enter ACFM of Air Side L in Side w in - Bag Dia2² π of Bags. Required as per Calculation.

M2 m3 Nm3hr m2. Interstitial Velocity FPM. Moldow baghouse filters since 1921.

A filter bag calculation can also be made because filter bags are round. E dust in gases f the particle in dust.

To determine the pressure drop caused by the filter bag follow these steps.

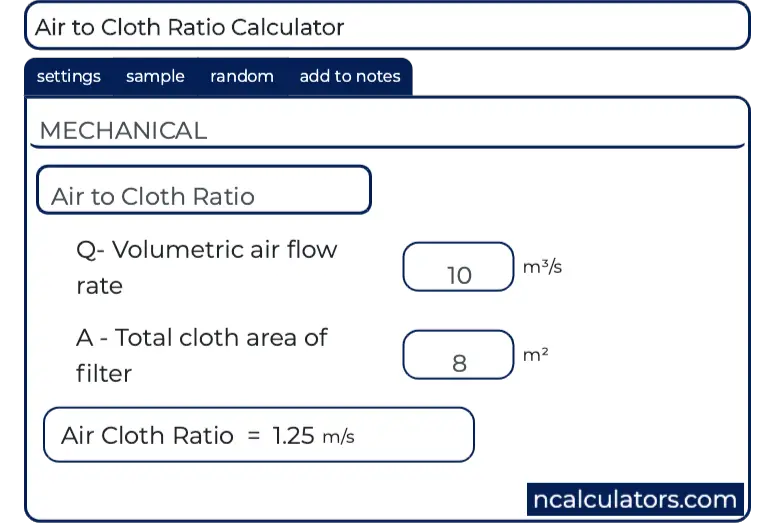

Filter housing less bag area Not to be confused with can velocity EXAMPLE. Step 1Select the type of bag micron rating and flow rate determine the pressure drop for water 1 cps 68F for a size 2 bag. Take the CFM of the system and divide it by the total filter cloth area to get your air to cloth ratio. These filters are commonly called baghouses. Then Click on Calculate To Find the Interstitial Velocity. To determine the appropriate filter size we must study the air. A filter bag calculation can also be made because filter bags are round. 87 Nm3h for the example. Dust Collection Research - Equipment Fortunately the basic equipment needed for good fine dust collection is not that We start with our tool or machine that creates the.

PULSE JET BAG FILTER DESIGN Where. Enter ACFM of Air Side L in Side w in - Bag Dia2² π of Bags. To determine the appropriate filter size we must study the air. Fabric filters collect particles with sizes ranging from submicron to several hundred. Collector by calculating the total filter area of each filter bag diameter x 314 x length 144 for number of inches in a square foot filter cloth area and then multiply that figure by the total number of bags in the collector. Air quantity Q2 035 m3s. PULSE JET BAG FILTER DESIGN 110000 120 50 100 Cement m3hr degree C gmm3 m.

Post a Comment for "Bag Filter Design Calculation Xls"